There has been a media buzz in recent years touting lithium-ion battery technology as a “magic bullet” for all of our energy storage challenges. Upon closer inspection, however, it has been revealed that, while lithium-ion batteries have a number of strengths, there exist numerous applications where Li-ion may not be the optimal choice. Furthermore, research and development efforts at Hammond Group have produced advances in lead acid battery chemistry which allow this proven technology to succeed as a viable alternative to Li-ion in important markets.

“Lithium-ion technology will require massive capital investment to achieve scale economies to make an affordable battery. We believe in-place lead-acid battery manufacturing and recycling assets can meet the needs of the energy storage market at an extremely competitive cost.”

— TERRY MURHPY, PRESIDENT AND CEO

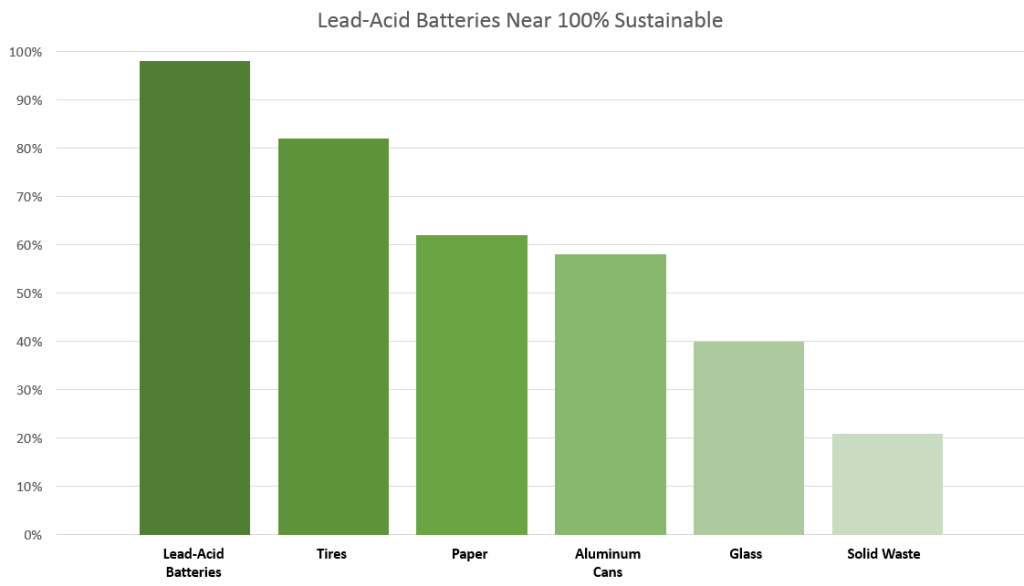

Lead-acid battery technology and its associated manufacturing process have been refined over many decades. The end result is a highly sustainable supply chain with lead being the most recycled product in the world. Recycling depleted lead-acid batteries provides a cost-competitive source of lead compared with mining, smelting, and refining operations. This provides a strong financial incentive for manufacturers to recycle as much lead as possible. This is in stark contrast to lithium which costs more to recycle than to exploit fresh natural resources. Because nobody has yet devised a cheap way to recapture lithium, firms must pay a recycling company to properly dispose of depleted batteries. This drives up the already high material cost of lithium batteries and reduces the financial incentive to recycle this scarce resource

In the past, lead-acid has underperformed against alternative technologies in high rate PSoC applications due to passivation of the negative active material and corresponding inadequate dynamic charge acceptance. Improved negative plate expanders have drastically improved charge acceptance and extended battery life significantly. Hammond Group has refined expander technology using state of the art research and development processes. The culmination of this effort is our advanced line of expanders that extend battery life while meeting the strenuous demands of high rate PSoC applications. By 2020, it is projected that over 90% of vehicles manufactured will utilize PSoC lead acid technology. The technology we have developed at Hammond Group is optimally positioned to meet this market need.

“Judged on the molecular-level of “energy density” lead may be a dull student. Judged on a systems-level, lead becomes a class star. The difference? On a systems level, lead-acid offers technical simplicity where all components are cheap and recyclable–using worldwide existing infrastructure.”

— TERRY MURPHY, PRESIDENT AND CEO

It is no secret that the energy storage discussion has been dominated by the single criterion of “power density” or energy-to-weight ratio. In the everyday world, however, the commercial metric of energy-to-weight per dollar upends the previous solution set to favor lead-acid batteries in many applications. This is especially true for green energy storage and power grid stabilization applications where weight plays no role. The rapid growth of green energy has created a vast new market for energy storage solutions. Lead-acid batteries provide the performance and value that this industry needs in order to power an increasingly energy-hungry planet.