In an ALABC (Advanced Lead-Acid Battery Consortium) report to the BCI Deep Cycling Committee, micro-hybrids were called “the choice of consumers”. Micro hybrid electric vehicles seem to represent the best compromise between desired fuel savings on one hand and affordability to the consumer on the other.

Battery demand forecasts for OEM micro hybrid electric vehicles in the years 2020-2025 range between 35 million to 90 million units.

While alternative technologies are on the rise, it is predicted that by 2025 lead acid batteries will still be the predominant technology to serve the classic SLI market segment as well as the micro-hybrid segment with stop-start, regenerative braking, and launch assist functions.

Stop-start and micro hybrid battery applications fall into the category of high rate partial state of charge (HRPSoC) operations.

This means a battery has to be able to accept a large range of charging amps at various states of charge. As the industry has found out over the past few years HRPSoC operation poses a whole new set of challenges for traditional lead acid battery designs.

Particularly it has been demonstrated that the negative plates of the batteries fail because of the development of dense, electrically inert films of lead sulfate on their surfaces. As a result the dynamic charge acceptance of the battery decreases significantly over time.

Hammond Expanders, a global leader of pre-blended expanders for lead-acid batteries, has long been conducting research in the field of advanced expander materials to help overcome such problems. “We started out by participating in ALABC funded research projects with other reputable industry partners, and have learned a lot in terms of material screening and the performance of different types of advanced carbons and lignosulfonates.

In recent years, our focus has been conducting independent research in order to build on our knowledge targeted on the interaction between the different expander components and the analysis of potential new materials”, said Achim Lulsdorf, Vice President of Product Development at Hammond Group.

Carbon has been demonstrated to counteract the accumulation of dense lead sulfate at the plate surfaces during HRPSoC cycling.

Various mechanisms were suggested to explain the positive effect of high carbon loadings (1%-3%) in the negative active material.

Previous ALABC work indicates that certain high structured conductive carbons with an optimized balance of particle size, porosity, and surface chemistry help to form a conductive matrix in the dense sulfate layer, thus breaking it up and allowing current to pass.

“We did not stop here. Recent Hammond studies have somewhat turned conventional wisdom upside down. The understanding that low lignosulfonate dosage levels would result in high charge acceptance performance does not necessarily apply when it comes to PSoC operation, said Lulsdorf.

“Furthermore standard J537 charge acceptance testing does not seem to be a reliable method for predicting dynamic charge acceptance and PSoC cycling performance. So, rather than focusing on individual expander components we started to look at the interaction of different lignosulfonates and advanced carbons.”

Hammond has maximized the interaction benefits by combining different materials at various dosage levels to accommodate the customer’s needs.

“We recognize that a one-size-fits-all approach would not be helpful to our customers. At this point in time there is no such thing as a universally accepted standard for micro hybrid batteries.” said Eric Holtan, Vice President of Sales and Marketing at Hammond Group. “Instead, batteries have to fulfill a wide range of requirements. While some customers strictly focus on HRPSoC cycle life, others demand moderate cycle life performance but also demand cold crank and capacity performance.”

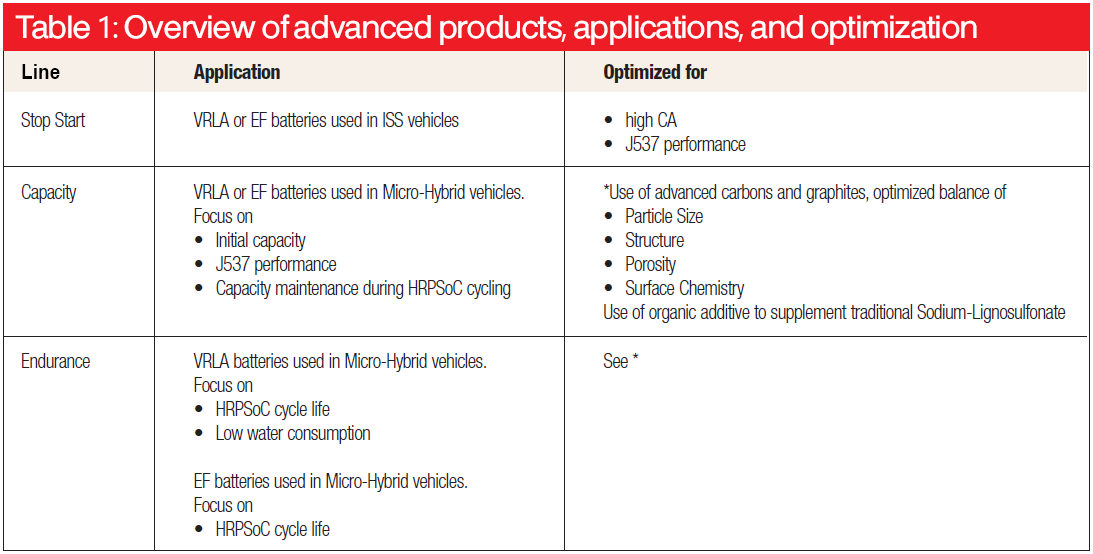

The new advanced expander product line reflects Hammond’s most recent development work and is the first comprehensive HRPSoC expander product line offered to the battery industry. Table 1 presents an overview of the various products.

Hammond would like to support your efforts in selecting the right product for your application.